Reverse Logistics Processes

The How of Reverse Logistics

Graphics courtesy of Yusen LogisticsOpens in new window

Graphics courtesy of Yusen LogisticsOpens in new window

The how viewpoint is meant to show how Reverse logistics works in practice, how value is recovered from products. |

Recovery is actually only one of the activities involved in the whole reverse logistics process. First there is collection, next there is the combined inspection/selection/sorting process, thirdly there is recovery (which may be direct or may involve a form of reprocessing), and finally there is redistribution (see Figure X-3).

Figure X-3. Reverse logistics processes | Credit: ResearchGateOpens in new window

Figure X-3. Reverse logistics processes | Credit: ResearchGateOpens in new window

|

Collection refers to bringing the products from the customer to a point of recovery. At this point the products are inspected, i.e. their quality is assessed and a decision is made on the type of recovery.

Products can then be sorted and routed according to the recovery that follows. If the quality is (close to) as-good-as-new, products can be fed into the market almost immediately through reuse, resale, and redistribution. If not, another type of recovery may be involved that now demands more action, i.e. a form of reprocessing.

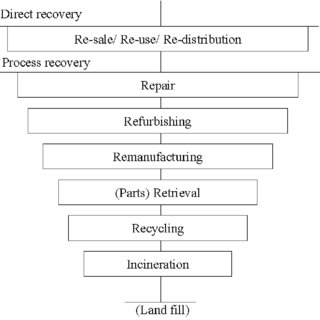

Reprocessing can occur at different levels: product level (repair), module level (refurbishing), component level (remanufacturing), selective part level (retrieval), material level (recycling), and energy level (incineration). Note that manufacturing is “as-good-as-new” recovery while refurbishing does not have to be so.

For other points of view on recovery/processing levels, see Fleischmann et al. (1997) and Goggin and Browne, (2000). This study does not particularly address repair systems, which is a body of literature on its own. At the module level, the product, e.g. a large installation, building, or other civil object, gets upgraded (refurbishment).

In the case of component recovery, products are dismantled and used and new parts can be used either in the manufacturing of the same products or of different products (remanufacturing).

In material recovery, products are grinded and their materials are sorted out and grouped according to a quality wish, so recycled materials can be put into raw material, such as paper pulp and glass.

Figure X-4. Recovery option inverted pyramid | Credit: ResearchGateOpens in new window

Figure X-4. Recovery option inverted pyramid | Credit: ResearchGateOpens in new window

|

Finally, in energy recovery products are burned and the released energy is captured (incineration). If none of these recovery process occur, products are likely to go to landfill.

Figure X-4 represents recovery options ordered as for the level of reprocess required, in the form of an inverted pyramid. At the top of the pyramid, we have the global levels, such as product and module, and at the bottom more specific levels like materials and energy.

Please note that returns in any stage of the supply chain (manufacturing, distribution, and customer) can be recovered according to options both from the top and from the bottom of the pyramid.

One can find overall similarities between the inverted pyramid above and the Lansink’s waste hierarchy, introduced in 1979 by this Dutch member of parliament as being prevention, reuse, recycling, and proper disposal. This principle has been adapted by other EU countries for their Waste Management regulations (see e.g. the German Recycling and Waste Management Act, 1996Opens in new window).

At first, one may think that recovery options at the top of the pyramid are of high value and more environmentally friendly than options close to the bottom, which recover less value from the products. We would like to stress that both thoughts are not necessarily true.

Originally, the Lansink’s hierarchy was put together regarding the environmental friendliness of the recovery option. Yet, the hierarchy is disputable even there. In the case of paper recycling versus land-filling, one may go against recycling by arguing that paper is biodegradable and requires less energy than the de-inking and bleaching processes necessary for recycling.

With respect to the economic value of each recovery option, that depends, for instance, on the existence of a matching market. Thus, it is possible that a used product has essentially no market value as such, but is very valuable as a collection of spare parts.

The Series:

- What Is Reverse Logistics?Opens in new window

- Forces Driving Companies to Engage in Reverse Logistics (Why-drivers)Opens in new window

- Reasons for Products Being Returned in the Supply Chain(Why-reasons)Opens in new window

- Reverse Logistics Processes: How are Returns Processed?Opens in new window

- Types & Characteristics of Returned Products: What Is Being Returned? Opens in new window

- Who Are Executing Reverse Logistics Activities? Opens in new window

- Barry, J., Girard, G., Perras, C. (1993): Logistics shifts into reverse. In: Journal of European Business 5, Sept./Oct. 1993, pp. 34 – 38.

- Ayres, R. U., Ferrer, G., Leynseele, T. van (1997): Eco-efficiency, asset recovery and remanufacturing. In: European Management Journal 15, pp. 557 – 574.

- Carter, C.R., Ellram, L. M. (1998): Reverse logistics: A review of the literature and framework for future investigation. In: Journal of business logistics 19, No. 1, pp. 85 – 102.

- Elkington, J., Knight, P., Hailes, J. (1991): The green business guide. Victor Gollancz, London.

- Fleischmann, M. (2001): Quantitative models for reverse logistics. Springer, Berlin et al.

- Harrington, L. (1994): The art of reverse logistics. In: Inbound logistics 14, pp. 29 – 36.