ISO 9000

Evolution of the ISO 9000 Standards

ISO 9000 standards were developed by the International Organization for StandardizationOpens in new window, a Geneva, Switzerland, organization founded in 1946.

The ISO 9000 standards were devised to promote the development of international standards and related activities, including conformity assessment (testing, inspection, laboratory accreditation, certification, quality system assessment, and other activities intended to assure the conformity of products to a set of standards and or technical specifications), to facilitate the exchange of goods and services worldwide.

That is why the organization chose ISO as the prefix for its numerical standards. It comes from the Greek root ISO which means equal. It is not an acronym for the International Organization for Standardization.

ISO is composed of nearly 200 technical committees and its members are from over 90 countries, with the U.S. member being the American National Standards Institute (ANSI)Opens in new window. The jurisdiction of the standards extends to all areas except those related to electrical and electronics engineering, which are covered by the International Electrotechnical Commission (IEC)Opens in new window.

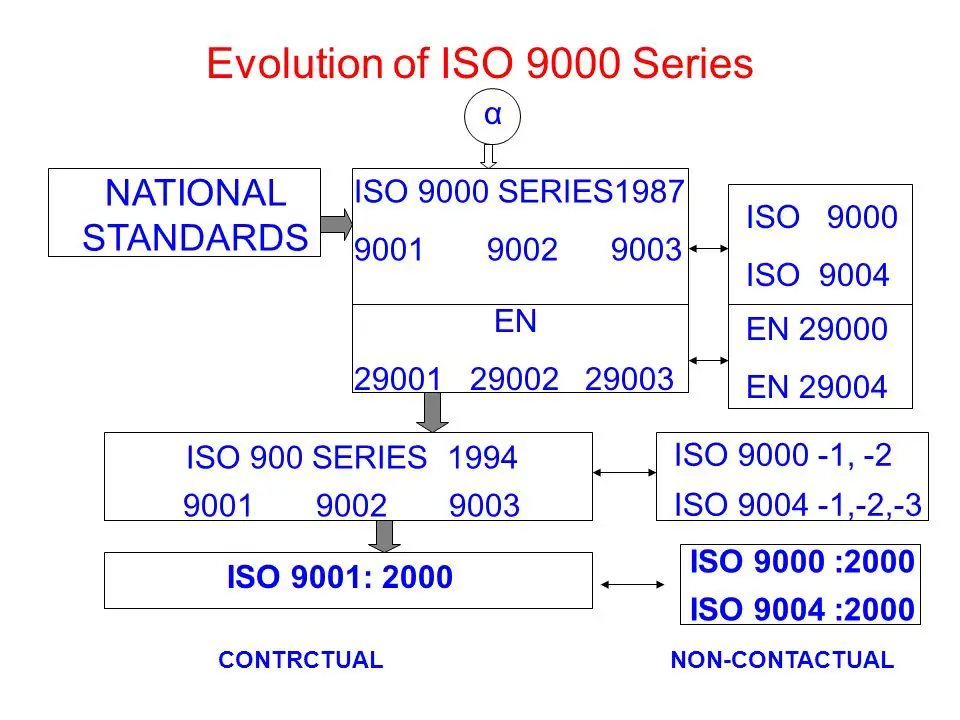

The results of ISO’s technical work are published as International Standards or Guides. Technical Committee 176 (ISO/TC176) on Quality Management and Quality Assurance began in 1979 on the ISO 9000 standards and it was first approved in 1987. Figure X-1 shows the evolution of the ISO standards.

Figure X-1. Evolution of the ISO 9000 Series standards

Figure X-1. Evolution of the ISO 9000 Series standards

|

The ISO 9000 series is the result of an evolutionary process and is composed of primarily five documents (ISO 9000–9004). The series describes three quality standards, defines quality concepts, and gives guidelines for using international standards on quality systems.

Contrary to what many believe, ISO 9000 does not apply to specific products and does not guarantee that a manufacturer produces a quality product (Stamatis, 1992).

The standards are generic and enable a company to assure (by means of internal and external third-party audits) that it has a quality system in place that meets one of the three published standards for a quality system.

An issue usually discussed in relation to the ISO is the question of: “Why the ISO standard?” The answer is a multiple one. However, fundamentally it has to do with the creation of the single Western European Market.

After long international negotiations, 12 separate became one. Most barriers to free movement of goods (free trade) are being removed. This fact alone presents an unprecedented level of opportunities, as well as considerable changes, for the organizations that want to participate.

To effectively trade with one another, and be assured that goods and services meet a consistent set of standards, agreed-upon quality standards had to be developed or accepted within the community.

The impetus for international standards was created by this movement toward a free market.

The European market is made up of 18 countries: 12 from the European Union (EU)Opens in new window (called the European Community until 1994), representing 320 million consumers, and six from the European Free Trade Association (EFTA)Opens in new window, representing 30 million consumers.

Table X-1 identifies the member countries.

| Table X-1 The European Market (350 Million Consumers) | |

|---|---|

| European Union (EU) | European Free Trade Association (EFTA) |

| Belgium | Austria |

| Denmark | Finland |

| France | Iceland |

| Greece | Norway |

| Ireland | Sweden |

| Italy | Switzerland |

| Luxembourg | |

| Netherlands | |

| Portugal | |

| Spain | |

| United Kingdom | |

By contrast, the United States represents 250 and Japan 120 milion consumers, respectively (Hagigh, 1992). These countries have developed bridging agreements or have trade market. The European Committee for Standardization (CEN)Opens in new window was mandated to develop harmonized versions of the ISO 9000 series, which are designated EN 9000.

All 16 member nations of CEN must adopt EN 29000 as national standards. To date 91 countries have signed an agreement to abide by these standards.

In the United States the movement has gained ground in several industries, such as steel, chemical, automotive, and electronics, and the U.S. government. The goal of this fast-paced movement is to allow individual organizations and governmental agencies the opportunity to:

- Define the quality system that is appropriate and applicable to a given organization.

- Demonstrate, to the customers, the commitment and management system to maintain quality.

- Compete in the international markets.

- Follow standard safety and product liability regulations and or procedures.

- Reduce cost and provide a practical, results-oriented target(s).

- Minimize supplier surveillance—through second-party audits.

- Provide a platform from which to launch a “continuous improvement” program such as total quality management (TQ), Malcolm Baldrige awards, and so forth.

- Involve all employees by stimulating understanding of quality systems.

- Levy, M. P. (1993). 20 Questions and Answers on the ISO 9000 Standards. Document No. Q101, rev. 1. Quality Systems Resource Facility, Troy, NY.

- MacLean, G. E. (1993). Documenting Quality for ISO 9000 and Other Industry Standards. Quality Press, Milwaukee, WI.

- Military Specification. (1956). MIL-Q-9858: Quality Control System Requirements. Superintendent of Documents, Washington, DC.

- Peach, R. W., Ed. (1992). The ISO 9000 Handbook. CEEM Information Services, Fairfax, VA.

- Voehl, F., Jackson, P., and Ashton, D. (1994). ISO 9000: An Implementation Guide for Small to Mid-sized Business. St. Lucie Press, Delray Beach, FL.