Core Technology

Understanding Organization's Core Technology

Today, every company is a technology-based company because Internet connectivity, automation Opens in new window, and new technologies like artificial intelligence Opens in new window are reaching into every facet of organizations.

In one survey of CEOs, technology topped the list of external forces that executives expect to significantly influence their organizations over the next few years.

Technology refers to the work processes, techniques, machines, and actions used to transform organizational inputs (materials, information, ideas) into outputs (products and services).

Technology is an organization’s production process and includes work procedures as well as machinery. An important theme in this literature is how core technology influences organization design.

Understanding core technology provides insight into how an organization Opens in new window can be designed for efficient performance.

An organization’s core technology is the work process that is directly related to the organization’s mission, such as teaching in a high school, medical services in a health clinic, or manufacturing at American Axle & Manufacturing (AAM) Opens in new window.

AT AAM, Opens in new window the core technology AAM, the core technology begins with raw materials (e.g., steel, aluminum, and composite metals).

Employees take action on the raw material to make a change in it (e.g., they cut and forge metals and assemble parts), thus transforming the raw materials into the output of the organization (e.g., axles, drive shafts, crankshafts, and transmission parts).

For a service organization like UPS, the core technology includes the production equipment (e.g., sorting machines, package handling equipment, trucks, and airplanes) and procedures for delivering packages and overnight mail. In addition, as at companies like UPS and AAM, computers and digital information technology have revolutionized work processes in both manufacturing and service organizations.

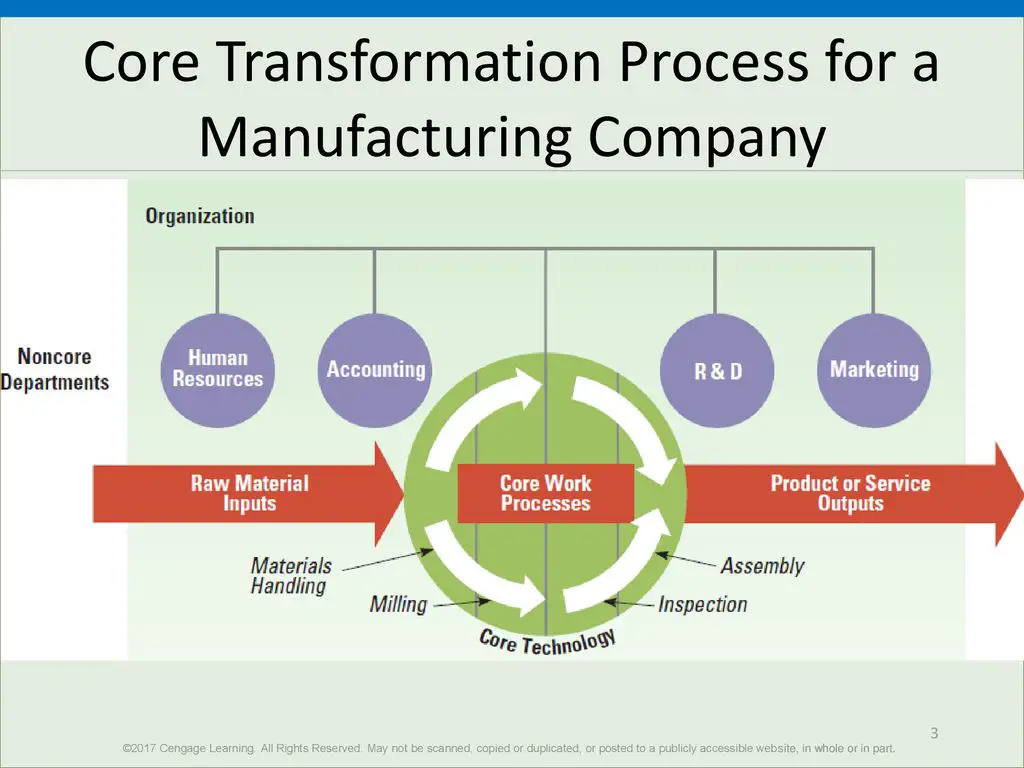

Figure X-1 features an example of core technology for a manufacturing plant. Note how the core technology consists of raw material inputs, a transformation work process (e.g., milling, inspection, assembly) that changes and adds value to the raw material and produces the ultimate product or service output that is sold to consumers in the environment.

Figure X-1 Core Transformation Process for a Manufacturing Company | Credit — Slideplayer Opens in new window

Figure X-1 Core Transformation Process for a Manufacturing Company | Credit — Slideplayer Opens in new window

In today’s large, complex organizations, core work processes vary widely and sometimes can be hard to pinpoint.

A core technology can be partly understood by examining the raw materials flowing into the organization, the variability of work activities, the degree to which the production process is mechanized, the extent to which one task depends on another in the workflow, or the number of new product or service outputs.

Organizations Opens in new window are also made up of many departments, each of which may use a different work process (technology) to provide a good or service within the organization.

A noncore technology is a department work process that is important to the organization but is not directly related to its primary mission.

In Figure X-1, noncore work processes are illustrated by the departments of human resources (HR), accounting, research and development (R&D), and marketing.

Thus, R&D transforms ideas into new products, and marketing transforms inventory into sales, each using a somewhat different work process. The output of the HR department is people to work in the organization, and accounting produces accurate statements about the organization’s financial condition.

You Might Also Like:

- Research data for this work have been adapted from the manual:

- Organization Theory and Design By Richard L. Daft